SPEED, PRECISION AND QUALITY

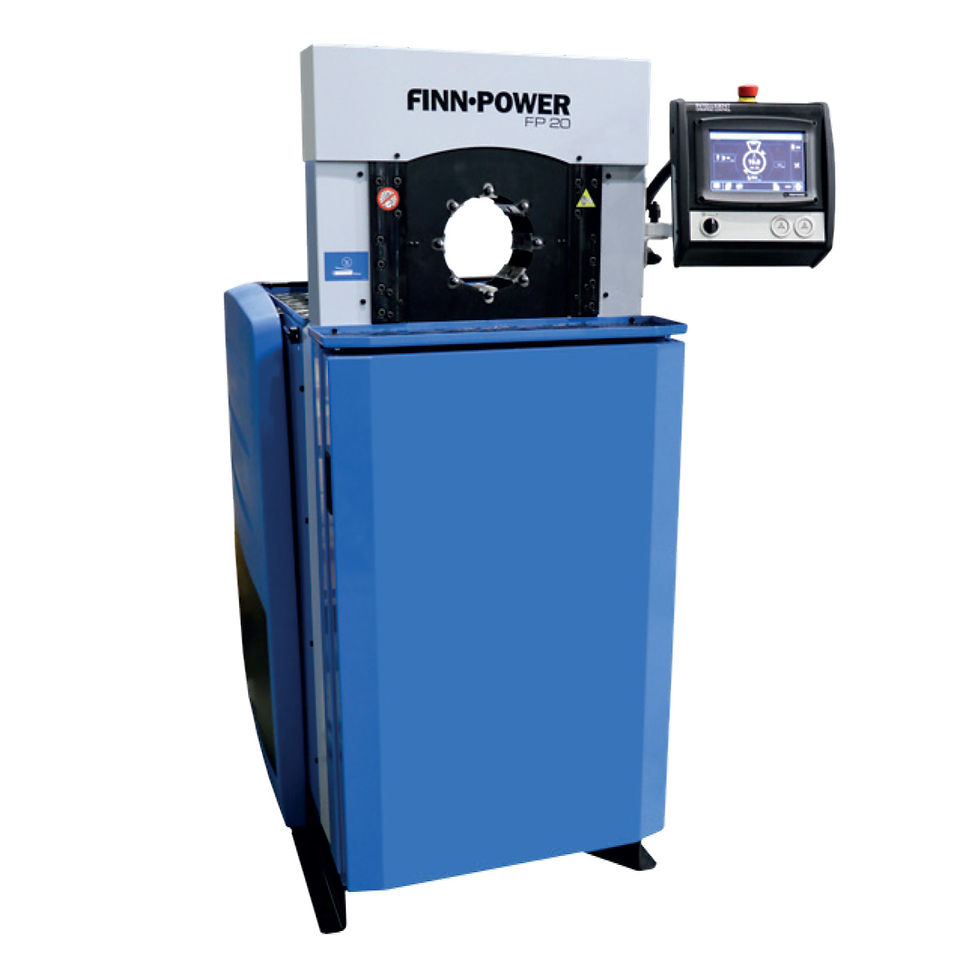

FP20 is the first step towards high scale production with automatic quality control and other advanced options.

FP20 is the powerful little brother of our famous FP120. It’s ideal for high volume production up to 1 1/2” 4-wire hydraulic hoses. It supplied with built-in die storage and Quick Change-tool as standard.

FP20 is available with separate hydraulic unit or as a compact model.

Control:

ICC (7” touchscreen) orSCC (3,5” display + control wheel)

FP20 also available in following configurations:

Z-model with separate crimping head and hydraulic unit

HB/HS-model with horizontal back and horizontal side

Standard Features:

Pressure crimping ICC1

Step crimping ICC2

QuickChange-tool

Electric backstop device

Mirror

Options:

Foot pedal

Mechanical back stop device

Interface pack ETH (Communication TCP/IP & UDP)

A3 signal (cable not included)

Oil cooler **

Combi unit (crimping and hydraulic unit combined)

Pinning support mandrel

Remote control (R1, R2)

Quality control ICC3

Graphical quality control ICC4

Bar Code Reader BCR

Speed adjustment **

Oil Condition Monitoring OCM

Industry 4.0

** Will have impact on motor size,

hydraulic unit dimensions and weight.

FP20

Max crimping dia (1) 61mm Max crimping force 1500KN Cycle time 10 mm (s) (2) 1.9 (S-model: 1.4) Hose size ID 11/2 (4SH) Die set series 20 Max opening (mm) (3) +68 Max opening without dies 152mm Master die D/L 84/97mm Motor Power 3.0 kW Oil tank volume 135L Dimensions

Length

Width

Height

1112mm713mm

1475mm

Weight 654 Kg 1) With standard dies. Crimping range can be increased with special dies.

2) Theoretical with 10mm cycle.

3) See table for die set data.

4) Maximum opening is the total die travel. Add this value to the minimum crimping diameter of the die set used. The result is the maximum opening of the machine with die set in place.